Partners

The Co-Patch consortium is made up of 15 organisations from eight European countries. Many of these partners (8) are R&D organisations, providing technical expertise and consultancy to the industry and among them there are two Classification Societies (BV and HRS).

All of these R&D organisations by the end of the project will be able to provide the developed technology to the industry, many of them being also actual patch repair contractors, that is end-users of the developed technology. There are also six SMEs in the consortium (AS2CON, CARDAMA, ENP, HRS, METTLE and SSA), three industrial partners (CARDAMA, ENP and UM) who will be also end-users of the developed technology and three university institutions (NTNU, NTUA and UniS). Some of the partners (BV, NTNU, NTUA and UniS) have broad experience with designing, modelling, testing and installing composite material patches on steel structures and this is shown from the large number of their relative publications.

Most of the partners have a very good knowledge of the structural configuration of ships and other large steel structures, thus being able in the initial stages to identify where patch repairs can be better applied. This identification will be finalised with the aid of the stakeholder forum.

BV, has extensive experience in using composite patches and composite materials in general in marine applications and, because of its activities as an established Classification Society, has access to many stakeholders. There also partners with high expertise in NDE methods (AIMEN, ISQ, TWI and NTNU), who can lead and share the activities for monitoring the structural integrity of the patch repaired structures.

Many partners in the consortium (AIMEN, ISQ, NTNU, NTUA, TWI and UniS) have high quality laboratory testing facilities, with expertise in testing and monitoring of composite materials. The number of available laboratories within the consortium is adequate for the purposes of the project, ensuring the successful and on time performance of all planned tests. The laboratory tests are approximately uniformly distributed among these partners. Some of the above partners (NTNU, TWI and UniS) together with some others (AS2CON, CARDAMA, ENP and UM) are also responsible for manufacturing the specimens and structures that will be tested. The common partners in these two activities guarantee the compatibility between the manufacturing and the testing specifications. The fabrication of small specimens involves all end-users participating in the project and most of the technology providers. The fabrication of patches for all tests (both laboratory and full-scale) is done by the repair contractors AS2CON, ENP and UM. Full-scale tests involve partners with high skills and experience in on site testing like AIMEN, CETENA, BV, NTNU and NTUA. NTUA, and specifically the Shipbuilding Technology Laboratory, has extensive experience in both laboratory and full-scale test measurements.

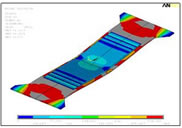

The FE modelling activities of the project will be carried out by partners having a great deal of experience in the numerical modelling of large steel structures, of composite materials and of composite patch repaired steel structures. These partners (AIMEN, AS2CON, CETENA, BV, HRS, ISQ, NTNU, NTUA and UniS) have experience with all major commercial finite element codes, either general purpose (NASTRAN, PATRAN, DYTRAN, ABAQUS, ANSYS, MARC, etc.) or specialised and in-house developed software. This fact, together with the number of these partners which is considered more than adequate, ensures the successful performance of the FE modelling tasks. CETENA, is very well equipped and experienced in executing and coordinating tasks of this type.

The majority of the R&D partners (AIMEN, AS2CON, CETENA, BV, HRS and TWI) together with two end-users (ENP and SSA) and two universities (NTUA and UniS) will carry out the work of developing the design procedures. These partners approach the subject from various angles ("Rules" concept from the classifications societies, academic approach from the university, straightforward and practically followed procedures from the technology providers and the yards), their complementarity ensuring the successful outcome of the effort. The presence of AIMEN, with all its corresponding expertise, makes certain the orientation of the developed procedures towards increasing the competitiveness of the European industry.

Partners CARDAMA, CETENA, ENP, BV, HRS, SSA and AS2CON have direct or indirect access to many ships and ship-owners or ship-operators, among which the final marine full-scale test cases will be selected. Partners like NTUA, AIMEN, ISQ and UniS have also close links to several national highway, railway or port authorities, among which the civil engineering full-scale test application will be selected. The complementary participation of R&D and university partners AIMEN, METTLE, NTNU, NTUA and UniS guarantees the successful performance of all corresponding design and experimental results assessment activities. The technology provider partners and the end-users are involved in all full-scale testing activities. Partners AIMEN, CETENA and BV have a large expertise in on site large-scale measurements and consequently, have also the responsibility for performing the tests.

All partners will take part in the dissemination of results, with TWI and the participating universities having a primary role. Results exploitation is ensured by the trade interests of the participating technology providers (AIMEN, CETENA, BV, HRS, ISQ, METTLE, TWI, AS2CON) and the special role of SSA as an association representing all UK shipyards and linked through CESA to all European shipyards. The technology providers cover almost all major industrial European countries, some of them (HRS and BV) addressing big maritime European industries. Finally, training on the basic results of the project is in the hands of TWI, which is considered as the most appropriate for that purpose organisation in Europe. TWI has an extensive experience in organising and performing training courses, providing to the consortium the means for ensuring that the project results will be accepted by industry as a robust way of carrying out repairs, in addition to ensuring that patch operators have the required level of competency.

With regards to the project coordination, the staff of the Shipbuilding Technology Laboratory (STL) of NTUA has more than 20 years experience in coordinating and carrying out research projects, funded by either the EC, national sources or the industry. In addition, the administration office of NTUA is also very experienced in managing research projects.

Since the basic objective of the proposed project is to identify design procedures in order to accept composite patches as permanent repairs and/or reinforcements of steel structures, the consortium's composition is oriented more towards R&D organisations (which will be the final technology providers) and end-users. The supporting theoretical calculations and patch monitoring activities are carried out by the participating three universities and by some of the R&D organizations themselves.

Four of the participating SMEs (AS2CON, HRS, METTLE and SSA) will be at the end of the project, providers of the developed technology, and two other participating SMEs (CARDAMA and ENP) will be simultaneously technology providers and end-users. With the developed technology, these SMEs will significantly increase the level of advanced "service-related" activities they will be able to offer to the surface transport industry.

Co-Patch Corsortium

Asociación de Investigación Metalúrgica del Noroeste (AIMEN), Spain

ALVEUS d.o.o. (AS2CON), Croatia

BUREAU VERITAS (BV), France

FRANCISCO CARDAMA S.A. (CARDAMA), Spain

CETENA S.p.A. (CETENA), Italy

Estaleiros Navais de Penische S.A. (ENP), Portugal

Hellenic Register of Shipping (HRS), Greece

Instituto de Soldadura e Qualidade (ISQ), Portugal

METTLE SARL (METTLE), France

National Technical University of Athens (NTUA), Greece

NORGES TEKNISK - NATURVITENSKAPELIGE UNIVERSITET (NTNU), Norway

Shipbuilders and Shipreperairs Association (SSA), United Kingdom

TWI Ltd, United Kingdom

The University of Surrey (UniS), United Kingdom

UMOE MANDAL AS (UM), Norway